NOTICE: The current version is a development version. Please wait for V1.0 before using any of these values!!

The Kremer-Grest (KG) model is the defacto standard for coarse-grain modeling of polymers using Molecular Dynamics. It represents a polymer as a string of beads. The beads are essentially hard spheres and the springs increase in stiffness to prevent chains from passing through each other. So far there is somewhat more than 1500 papers studying various aspects of polymer physics using the KG model. The KG model is a generic model, and was not designed to match any particular specific polymer chemistry.

Below is a tool for 1) mapping real polymers to a Kuhn representation, and 2) deriving a Kremer-Grest model matching a given Kuhn representation, that we have developed based on our recent papers on Kuhn mapped KG models. Combining the two, we can derive a KG model matching the large scale emergent properties of any commodity polymer species.

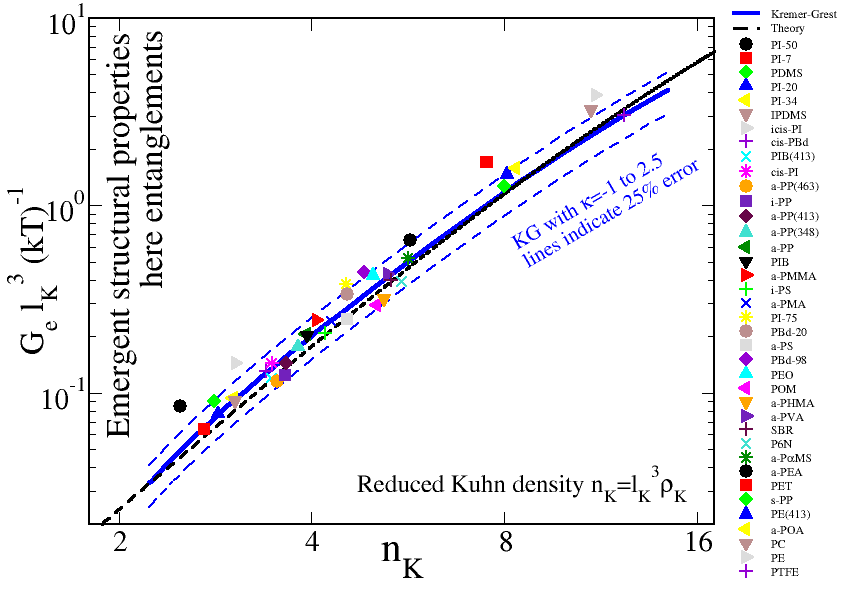

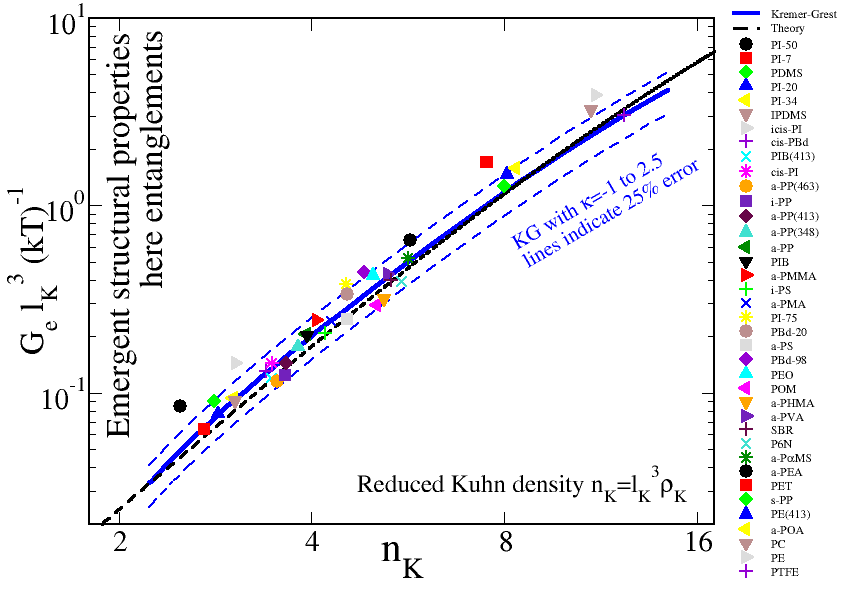

Our mapping is based on Univerality rather than explicit coarse-graining. Universality suggests that all physical properties (for concentrated polymer solutions/melts above the glass-transition temperature) depends on just two numbers. The Kuhn number which determines the chemistry of the polymers, we want to describe, and the number of Kuhn segments per chain describes the chain length of the polymer melt we are targetting. The plot above shows how by varying a single parameter - the chain stiffness - we can design KG polymer models that match fairly accurately the entanglement modulus of most commodity polymers (symbols). The entanglement modulus is just one univeral emergent quantity, we expect all other universal emergent quantities to be equally well matched.

Note that if you are interested in studying e.g. glassy dynamics or other non-universal properties which depends critically on the specific monomeric structure and interactions, then the current approach will most probably fail. You might use well equilibrated KG polymer models as a stepping stone to specific coarse-grained models or models based on atomistic force fields.

Please cite the papers and site, if you use the mapping tool:

Below is our online tool for mapping real polymers to a Kuhn description, and mapping a Kuhn description to a KG model. If you already have a Kuhn mapping you can jump to "Kuhn mapped KG model" and enter the numbers to generate a corresponding KG model. If not, then start by entering the single chain properties. Clicking Calculate will derive quantities that you need to propagate the properties.

Please enters the single-chain properties below or choose a polymer from the Polymer Handbook

Mean square extension per unit mass <R^2>/M = (Å^2/[g/mol])The maximal length is the length if you pull the chain to a straight line, but retaining the molecular structure due to valence angles. For say a PE chain, Rmax=L cos(theta/2) = 0.83*L, L total contour length of back-bone bonds, and theta=68 degrees the valence angle of a C-C-C bond.

Additional parameters are needed for the Kuhn description:

Temperature T= (K)

If you have derived the KG force field above, then

to generate a LAMMPS script for running the force field

In case of questions, bugs, etc. please contact Carsten Svaneborg at zqex(at)sdu(dot)dk

This page is copyright Carsten Svaneborg, 2020